Good thing we've learned from previous encounters with these bad plans to draw or cut out parts on something other than the piece of wood we'll actually be using. We drew the rudder, following the plans exactly, on a piece of thick white paper. Then we put the paper rudder with the rudder stock and spacer, and lo and behold, nothing matched up.

So, thinking that of course we probably don't know what we're doing, just being amateurs, we triple checked all of our measurements. There were a couple problems stemming from inexperience or mismeasuring, we presume.

1. Tiller was about 10mm too short - this was an easy fix. We just cut off 10 more mm of red cedar away from the center maple piece so that the back end of the tiller sticks out of the rudder case far enough, making the tiller a bit shorter, but that shouldn't really matter.

2. Rudder stock spacer was a tiny bit too long, but that will get sanded when we're all done. Also, we had to cut out more of the curve in the spacer because the point where our pivot bolt will be to the edge of the spacer was about 10mm short. (Supposed to be 65mm, and ours was about at 55, depending).

Then it was time to tackle the f-ing mess (not our mess). The top of the rudder did not fit into the rudder stock! With the pivot holes lined up, the top of the rudder was overlapping the spacer inside the stock - which does not work with two pieces of wood - one cannot overlap another!! If we moved the pivot hole in the rudder so that we could actually pivot it around inside the stock, it wouldn't match up with the stock on the outside edge this time. It's hard to explain, but basically when the rudder is down when sailing along, it fit fine, but when it is raised (kicks up if you hit bottom or an oyster bar) the rudder would hit the stock at about 45 degrees or less, so the rudder would still be sticking way down into the water - but it should be at about a 90 degree angle with the stock so that it won't still be hitting things in the water. Additionally, the knob called for on the plans where the uphaul rope should go wasn't working into the design well, so we decided to chop that off and move the uphaul back on the rudder some to gain more leverage.

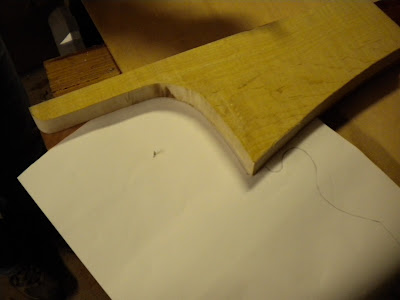

Above: see how the pencil line is being covered by the piece of wood - that's the theoretical rudder overlapping with the spacer - impossible.

Below: The rudder forced to pivot up to 90 degrees - in order for this to be possible, had to move way away from the pivot point, actually to past the top end of the rudder - but wait, you say, there's no wood there to put a bolt through. That's exactly right.

So to redesign the rudder we took a fresh piece of paper, keeping the same lines and measurements on the bottom and sides of the rudder. Then we put the piece of paper in between the stock and spacer and lined up the trailing edge of the rudder with the end of the rudder stock. We then stuck a nail up through the handy pilot hole we had drilled through the epoxy for the bolt, and stuck that nail through the paper rudder as a pivot. Then we pivoted the paper rudder along until it was raised, where we were able to draw the outline of the spacer onto the paper to show where the rudder will stop when it is raised and comes in contact with the stock spacer. This worked really well, and we drew a nice curve along the inside of the spacer on our paper for the top part of the rudder.

From the new paper rudder, we transferred the rudder onto a piece of scrap plywood, cut this out and tested it with the entire rudder stock and spacer before actually drawing and cutting anything on our real rudder. The plywood test rudder worked perfectly, so we traced it onto our cedar and maple strips and cut it out! Hoorah, it fits and works properly. We are awesome boat builders. And we're never buying John Welsford plans again - if we pay for plans, we feel that we should be able to follow the plans as they are written and build a well-designed boat. We shouldn't have to be discovering errors and figuring out how to change them to make a boat fit together and float!

Above: see how the pencil line is being covered by the piece of wood - that's the theoretical rudder overlapping with the spacer - impossible.

Below: The rudder forced to pivot up to 90 degrees - in order for this to be possible, had to move way away from the pivot point, actually to past the top end of the rudder - but wait, you say, there's no wood there to put a bolt through. That's exactly right.

Below: The rudder from the plans over our redesigned rudder. The bottoms are lined up, showing how the plans rudder (pencil pointing to it) is way too short with the pivot hole waaaaaaay off.

From the new paper rudder, we transferred the rudder onto a piece of scrap plywood, cut this out and tested it with the entire rudder stock and spacer before actually drawing and cutting anything on our real rudder. The plywood test rudder worked perfectly, so we traced it onto our cedar and maple strips and cut it out! Hoorah, it fits and works properly. We are awesome boat builders. And we're never buying John Welsford plans again - if we pay for plans, we feel that we should be able to follow the plans as they are written and build a well-designed boat. We shouldn't have to be discovering errors and figuring out how to change them to make a boat fit together and float!

No comments:

Post a Comment