This feels like real progress!! Last weekend we finally flipped the boat over. Daddy prepared by unscrewing all of the legs from the strongback (ladder on the floor), then we laid out burlap and boat cushions to protect the hull, and brought over one more strong body to lift the boat. Carried it outside and turned it over. It was a lot lighter than we were expecting, which is good.

We unscrewed the legs from the frames, and got it looking almost like a real boat.

She is very wide - my dad calls her a tub. We'll see what it feels like in the water. Here you can really see what the insides look like now with the frames that we started construction with, to the seat supports and stringers running the length of the boat, the centerboard case, and the side, chine, and bottom panels.

There is much sanding in our future - this area between frames one and two is open, so all the messy epoxy has to be cleaned up and looking nice and smooth before we paint. The mast will come down to the mast step towards the front of this area. In front of frame one (the big piece with a hole in it) will be a compartment with an access port, and a deck over the top.

Once we were finished admiring, we carried the boat back into the carport and rested it back on the strongback, padded with burlap bags.

The bow seems really tall - I think it should have a figurehead.

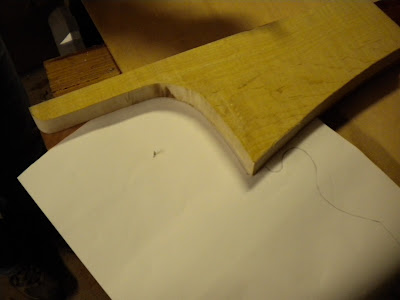

We cut off the remaining piece of plywood sticking out of the bow and cut down the side panels flush with the top of the frames.

An exciting weekend!